Engineering the Future: Amiable's Leadership as an Exothermic Welding Manufacturer in Earthing Products and Thermit Welding

Born from a Vision. Driven by Innovation.

Amiable Impex is more than just a manufacturer; it’s the brainchild of Mr. Maulik Shah, a visionary leader with over a decade of experience in the electrical metal industry. Founded with the ambition to lead both India and the world in its domain, Amiable Impex has charted a path of continuous growth and innovation as a trusted :

(Factory in Palghar - Hamrapur Wada, Maharashtra - Mumbai).

We manufacture as per IEEE 837-2014 Std and our Powder is UL Certified.

(Factory in Palghar - Hamrapur Wada, Maharashtra - Mumbai).

We are approved in Indian Railways (RDSO)

(Factory in Palghar - Hamrapur Wada, Maharashtra - Mumbai).

We manufacture as per IEC 62561-2 standard and our Rod is UL Certified.

(Factory in Palghar - Hamrapur Wada, Maharashtra - Mumbai).

We manufacture as per IEC 61238-1-2018 & AS/NZ 4325.1:1995 - Amendment 1

Kindly check our Factory Video:

(Factory in Jamnagar & Palghar).

We manufacture as per IEC 62444:2010 standard

(Factory in Palghar, Maharashtra)

(Factory in Palghar – Hamrapur Wada, Maharashtra – Mumbai)

We manufacture as per IEC 62561-5 standard.

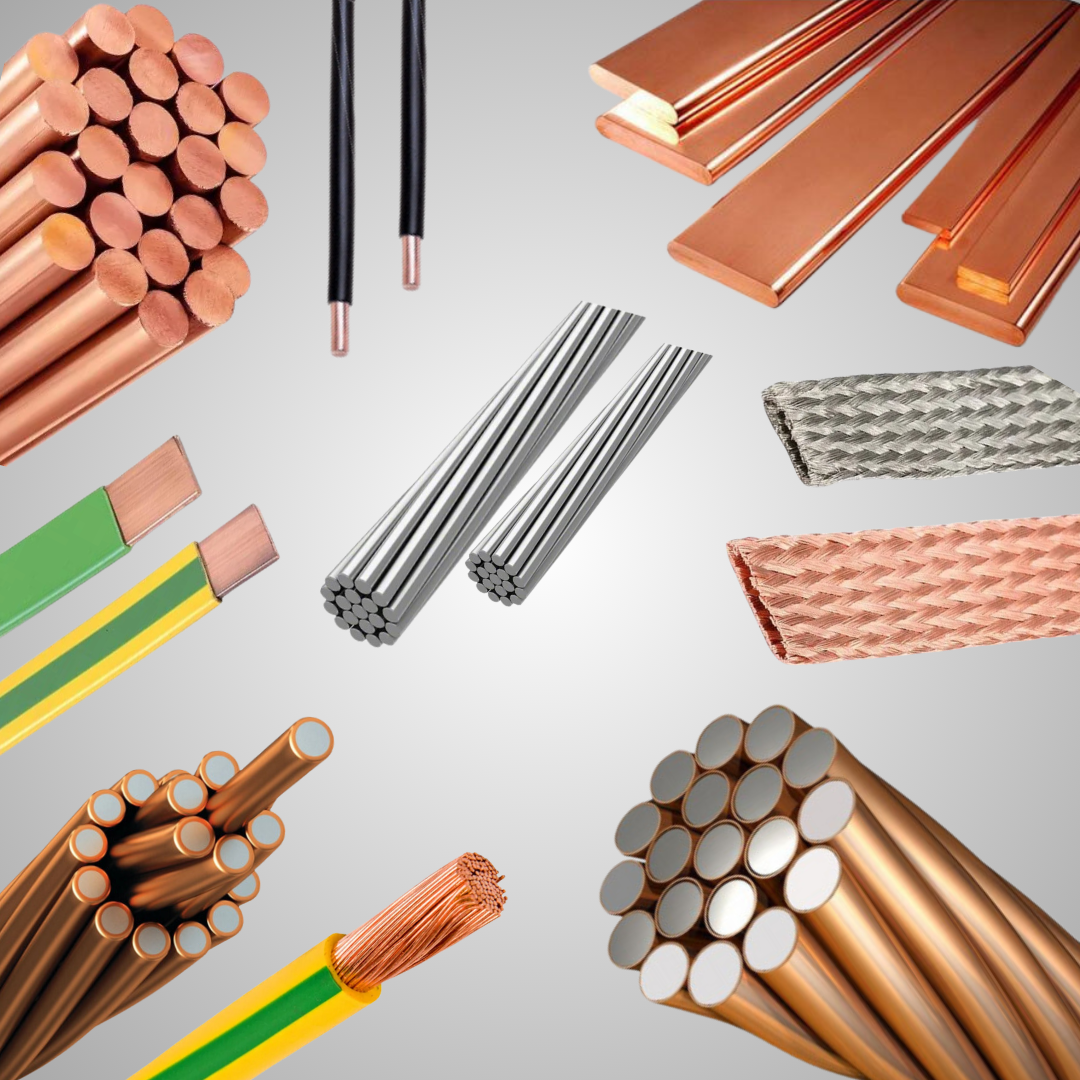

Crafting Quality : Explore Our Diverse Manufacturing Portfolio

Exothermic Welding Process: Trusted by Leading Exothermic Welding Manufacturers

The exothermic welding process is a highly efficient and reliable method used to join metals through an exothermic reaction. This process generates extreme heat, allowing metal components to melt and fuse without the need for external power sources. As a leading Exothermic Welding Manufacturer, Amiable Impex specializes in providing top-tier exothermic welding solutions for industries like electrical grounding, railway tracks, and other heavy-duty metal applications.

How Does Exothermic Welding Work?

In exothermic welding, a mixture of metal oxides and fuel (typically aluminum powder) is ignited, triggering a chemical reaction that produces molten metal at high temperatures. The molten metal then flows into the mold, fusing the metal components together to form a permanent bond. This technique stands out for its reliability, as it requires no external power source, which makes it a cost-effective and efficient solution trusted by Exothermic Welding Manufacturers worldwide.

Advantages of Exothermic Welding: Why Leading Exothermic Welding Manufacturers Prefer It

- High Strength and Durability: The molten metal produced in the reaction ensures strong and permanent bonds, making it ideal for heavy-duty applications.

- Cost-Effective: Since exothermic welding does not require expensive power equipment, it reduces overall operational costs.

Download Brochure!

- Precision and Quality: Exothermic welding ensures precise, high-quality welds that are essential in electrical and telecommunications connections.

- No External Power Required: The exothermic reaction itself generates the heat needed for welding, eliminating the need for external gas or electricity.

- Environmentally Friendly: The process uses eco-friendly materials, making it a sustainable and efficient choice for industries.

As a premier Exothermic Welding Manufacturer, Amiable Impex offers tailored exothermic welding solutions, including molds, Exothermic Welding powders, and accessories that guarantee precision, durability, and efficiency.

Applications of Exothermic Welding by Exothermic Welding Manufacturers

Exothermic welding is widely applied across several industries that require reliable, high-strength metal connections. Some of the major applications include:

- Electrical Grounding: Providing long-lasting, efficient connections for electrical systems and equipment.

- Railway Track Welding: Ensuring durable welds that can withstand the stresses of high-traffic railway systems.

- Heavy Electrical Connections: Used in critical electrical connections for transformers and generators, where reliability is crucial.

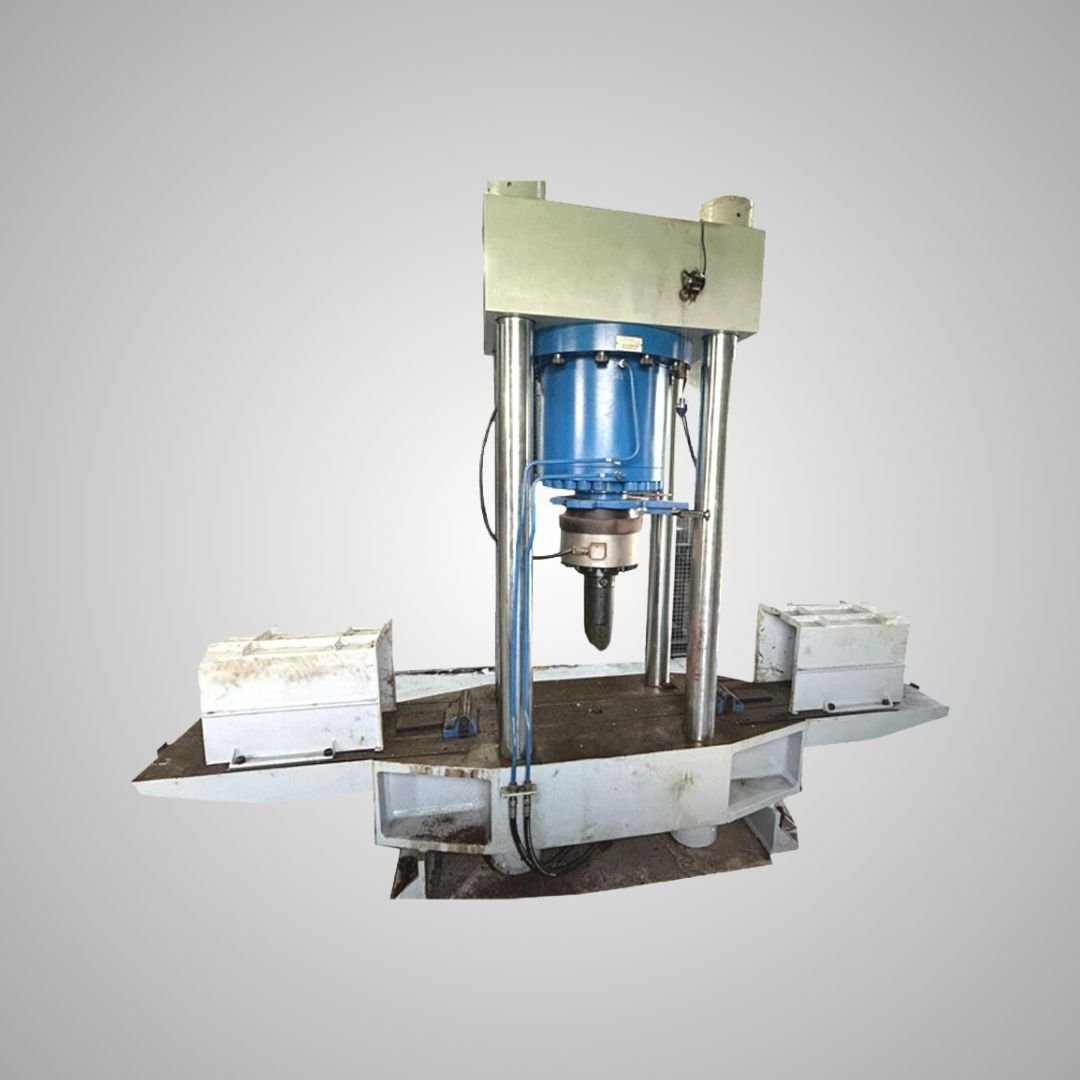

Our Facilities - Manufacturing Operations

An automatic weigh batcher plays a pivotal role by precisely measuring and dispensing the essential components, like aluminum powder and iron oxide, in the exact proportions required for the thermite welding process. This ensures the consistency and integrity of welds in railway tracks.

Physical Test

Mechanical Test

The Brinell Hardness Machine (3000 Kg) is a powerful and precise testing instrument used to measure the hardness of materials. With a testing force of 3000 kilograms. This machine provides reliable data for quality assurance and material selection, helping ensure the durability and performance of components and structures.

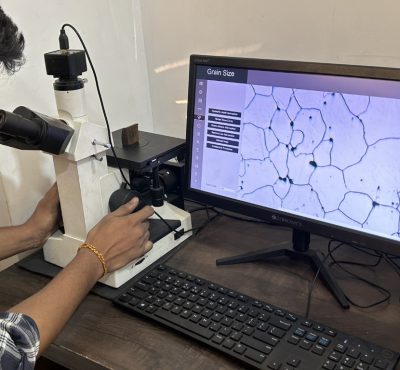

Metallurgical Test

A spectrometer is used to analyze the chemical composition of various metal. By measuring the element content, it ensures the quality and consistency of welds in railway tracks and other applications, crucial for maintaining the structural integrity and safety of rail infrastructure.

Chemical Test

Why Choose Amiable Impex as Your Exothermic Welding Manufacturer?

As a leading Exothermic Welding Manufacturer, Amiable Impex offers top-tier exothermic welding solutions tailored to meet the needs of industries requiring reliable and long-lasting metal connections. With a strong focus on quality, precision, and customer satisfaction, we have established ourselves as a trusted name in the exothermic welding sector.

Here are some reasons why you should choose Amiable Impex as your preferred Exothermic Welding Manufacturer:

High-Quality Products: We manufacture exothermic welding systems, including molds, powders, and accessories, with the highest standards of quality and precision.

Innovative Solutions: We stay ahead of industry trends by continuously improving our products and processes, ensuring you get the most efficient and reliable welding solutions.

Customer-Centric Approach: We offer personalized solutions tailored to meet your specific welding needs, helping you achieve optimal results.

Experienced Team: Our team of experts has years of experience in exothermic welding, ensuring that every product is crafted to perfection.

Cost-Effective Solutions: By providing high-quality products at competitive prices, we help you achieve cost savings without compromising on quality.

Global Reach: Our products serve industries worldwide, from electrical grounding to railway track welding, ensuring a versatile and reliable solution for all your welding needs.

Choose Amiable Impex for your exothermic welding requirements and experience the difference in quality and service.

Excellence in Every Detail: Our Uncompromising Commitment to Quality

Exploring Our Precision Testing Tools

FAQ's

What is Exothermic Welding?

Exothermic welding, also known as thermite welding, is a chemical process used to create strong, permanent, and highly conductive metal connections. This technique utilizes a mixture of aluminum powder and metal oxides to generate an exothermic reaction, producing molten metal that fuses the components. Amiable Impex, as a leading Exothermic Welding Manufacturer, offers high-quality solutions for various industrial applications, including electrical grounding and bonding.

What is an Exothermic Welding Mold, and What is Its Use?

An exothermic welding mold is a graphite mold used to contain the welding reaction and shape the molten metal into the desired connection form. The mold ensures precise, uniform results and can be customized for specific applications. At Amiable Impex, we manufacture molds that are durable and efficient, supporting our role as a trusted Exothermic Welding Manufacturer.

How Does Exothermic Welding Work?

Exothermic welding involves a chemical reaction where aluminum powder reacts with metal oxides to generate intense heat, melting the materials to create a permanent bond. This reaction takes place in a specially designed mold, ensuring a clean and precise connection. As an experienced Exothermic Welding Manufacturer, Amiable Impex provides complete solutions, including welding powder, molds, and accessories.

How to Perform Exothermic Welding?

- Prepare the Surfaces: Clean and align the metals to be joined.

- Set Up the Mold: Place the components in the exothermic welding mold and secure it.

- Add Welding Powder: Pour the exothermic welding powder into the mold.

- Ignite the Powder: Use a spark or flint gun to ignite the powder.

- Allow Cooling: Let the molten metal cool and solidify.

- Remove the Mold: Open the mold to reveal the completed weld.

As a reliable Exothermic Welding Manufacturer, Amiable Impex provides all the necessary materials and guidance for seamless execution.

What is the History of Exothermic Welding?

Exothermic welding was first developed in the early 20th century for railway applications. Its ability to create maintenance-free, corrosion-resistant connections quickly made it popular across industries. Over the years, advancements have improved its efficiency and safety. Today, Amiable Impex, a leading Exothermic Welding Manufacturer, builds on this legacy by offering innovative solutions for modern industrial needs.

What are the Advantages of Exothermic Welding?

- Durability: Creates permanent, corrosion-resistant connections.

- High Conductivity: Ensures superior electrical performance.

- Maintenance-Free: Does not require ongoing upkeep.

- Versatility: Suitable for various metals and applications.

- Cost-Effective: Offers long-term reliability, reducing future expenses.

Choose Amiable Impex, a trusted Exothermic Welding Manufacturer, for reliable products that maximize these benefits.

What is the Maximum Temperature in Thermite Welding?

The temperature during the thermite welding process can exceed 2500°C (4500°F), enough to melt most metals and create a strong bond. As a renowned Exothermic Welding Manufacturer, Amiable Impex provides high-quality materials capable of handling such intense temperatures.

Which Type of Welding is Used for Railway Tracks?

Exothermic welding, also known as thermite welding, is the preferred method for joining railway tracks. It provides durable and seamless connections, essential for the heavy loads and vibrations experienced by railway systems. Amiable Impex, as a trusted Exothermic Welding Manufacturer, supplies the tools and materials required for this critical application.

What is the Cleanest Type of Welding?

Laser welding is often considered the cleanest type of welding because it produces minimal spatter, smoke, or debris. However, in terms of traditional methods, exothermic welding is also exceptionally clean as it eliminates the need for external power sources or additional materials that can create waste. Amiable Impex, a leading Exothermic Welding Manufacturer, ensures that its products contribute to cleaner and more efficient welding processes.

What is Alumino Thermite Welding?

Alumino thermite welding is a specialized process that uses a mixture of aluminum powder and metal oxides to produce an exothermic reaction. This reaction generates molten metal, which is used to weld components together. It is widely employed in industries like railway construction and electrical grounding due to its strength and durability. As a prominent Thermit Welding Manufacturer in India, Amiable Impex provides top-quality materials and solutions for this advanced welding technique.

Why is Aluminum Used in Thermite Welding?

Aluminum is used in thermite welding because of its high affinity for oxygen. During the thermite reaction, aluminum reacts with metal oxides to release intense heat, which melts the metals and forms a strong bond. This property makes aluminum an ideal choice for generating the temperatures required in thermite welding. Amiable Impex, a leading Thermit Welding Manufacturer, ensures the use of premium-grade materials to deliver efficient and reliable welding solutions.

How Do You Use Thermite to Weld?

- Prepare the Area: Clean and align the metal components to be welded.

- Set Up the Mold: Place the mold around the joint area and secure it properly.

- Add Thermite Material: Pour the thermite mixture into the mold.

- Ignite the Thermite: Use a flint gun or spark to ignite the mixture.

- Allow the Reaction: The exothermic reaction generates molten metal, fusing the components.

- Cool and Remove: Let the weld cool and then remove the mold to reveal the joint.

As a trusted Thermit Welding Manufacturer in India, Amiable Impex offers comprehensive kits, including thermite powder, molds, and accessories, ensuring seamless execution.

What is Pressure Thermite Welding?

Pressure thermite welding is a variation of the thermite welding process where pressure is applied to the molten metal during the reaction. This ensures better fusion and minimizes voids in the weld, making it ideal for critical applications such as railway tracks and heavy electrical connections. As an experienced Thermit Welding Manufacturer, Amiable Impex provides tailored solutions for pressure thermite welding, ensuring reliability and precision in every weld.

What is Non-Pressure Welding?

Non-pressure welding is a process where metal parts are joined without applying external pressure during the weld. Instead, heat is used to melt the metals at the joint, allowing them to fuse naturally as they cool. This method is particularly effective for creating high-quality and durable connections. As a leading Exothermic Welding Manufacturer, Amiable Impex offers advanced non-pressure welding solutions, ideal for applications like grounding and electrical connections.

What Are the Advantages of Thermite Welding?

Thermite welding, a form of exothermic welding, offers several advantages:

- Durability: Produces strong, permanent joints that withstand high stress.

- Efficiency: Requires no external power source for the welding process.

- Versatility: Suitable for various materials, including steel and copper.

- Corrosion Resistance: Ensures long-lasting joints with minimal degradation.

- Cost-Effective: Reduces the need for expensive machinery or equipment.

As a trusted Exothermic Welding Manufacturer, Amiable Impex provides premium thermite welding materials and accessories to maximize these benefits.

What Are the Advantages of Thermite Welding?

Thermite welding, a type of exothermic welding, requires the highest temperatures among welding techniques. The exothermic reaction in thermite welding can reach temperatures of approximately 2,500°C, making it suitable for heavy-duty applications like railway track welding and grounding. Amiable Impex, a renowned Exothermic Welding Manufacturer, specializes in providing high-temperature welding solutions tailored to industrial needs.

How is Copper Used in the Welding Process?

Copper is commonly used in welding as:

- Base Material: For joining copper components, especially in electrical applications.

- Filler Material: In certain welding processes where copper alloys are required.

- Heat Conductor: Its high thermal conductivity ensures efficient heat distribution.

Amiable Impex, a premier Exothermic Welding Manufacturer, specializes in providing solutions for welding copper, ensuring high-quality joints for electrical grounding and other applications.