Copper Ring Tongue Type Lugs (Brazed) (Brazed, Insulated & Pre Insulated)

Copper Ring Tongue Type Lugs, when brazed, stand as a testament to the evolution of electrical connectivity solutions. Crafted from high-quality copper and subjected to a brazing process, these lugs play a pivotal role in establishing secure and efficient electrical connections in various industrial applications. The brazing technique involves joining metals at high temperatures, ensuring a robust and enduring bond.

Exceptional Conductivity: Copper’s inherent conductivity is amplified by the brazing process, providing an uninterrupted flow of electrical current and optimizing overall system performance.

Durable Brazing Technique: The brazing method results in a durable connection, capable of withstanding mechanical stress, vibrations, and fluctuations in temperature, ensuring longevity in challenging industrial environments.

Versatility in Applications: Copper Ring Tongue Type Lugs find applications across diverse industries, including power distribution systems, control panels, and machinery wiring, showcasing their versatility and adaptability.

Secure Wire Termination: The ring tongue design facilitates a secure termination of wires, preventing fraying and enhancing the stability of electrical connections.

Brazed, Insulated & Pre-Insulated Options: These lugs are available in brazed, insulated, and pre-insulated variations, providing solutions for various wiring needs. The insulation ensures an added layer of safety and protection against electrical hazards.

Compliance with Standards: Meeting industry standards and regulations, Copper Ring Tongue Type Lugs (Brazed) adhere to strict quality measures, assuring users of their reliability and safety.

Easy Installation: Designed for straightforward installation, these lugs contribute to time efficiency in wiring applications, reducing labor costs.

Corrosion Resistance: The inherent properties of copper, combined with the brazing process, result in lugs that resist corrosion, contributing to their durability and minimizing maintenance requirements.

Temperature Stability: Copper’s ability to withstand varying temperatures ensures consistent performance even in environments with extreme temperature conditions.

Cost-Effective Solutions: The longevity, reliability, and efficiency of Copper Ring Tongue Type Lugs make them a cost-effective choice for industries seeking robust electrical connections.

In conclusion, the brazed variant of Copper Ring Tongue Type Lugs, available in insulated and pre-insulated forms, epitomizes excellence in electrical connectivity, meeting the demands of modern industrial applications with precision, reliability, and safety.

Copper Ring Tongue Type Lugs (Brazed) (Brazed, Insulated & Pre Insulated)

Copper Ring Tongue Type Lugs represent a cornerstone in electrical connectivity, offering a range of options to cater to various industrial requirements. Available in Non-Insulated, Insulated, and Pre-Insulated types, these lugs stand out for their exceptional conductivity, reliability, and adaptability in diverse applications.

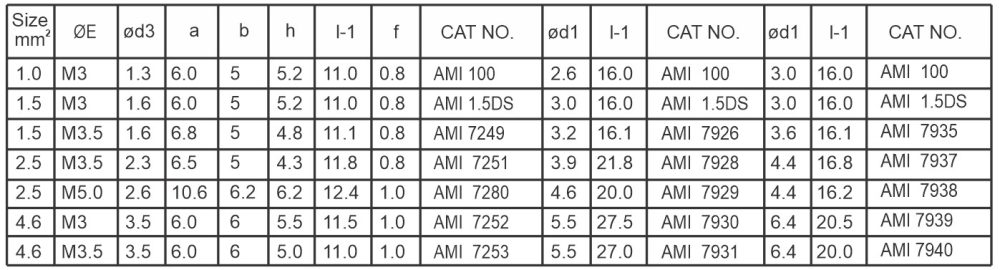

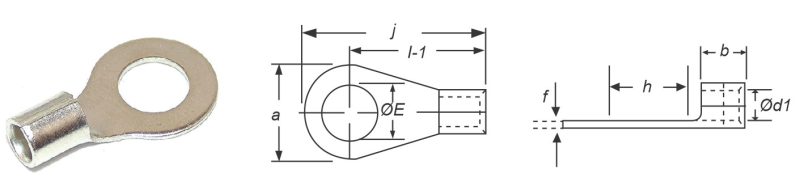

Non-Insulated Copper Ring Tongue Type Lugs:

- Designed for applications where insulation is not a primary concern.

- Ideal for environments where space constraints demand a compact yet robust solution.

- Ensures a secure and stable termination of wires, preventing fraying and enhancing overall connection reliability.

- Well-suited for use in control panels, power distribution systems, and machinery wiring.

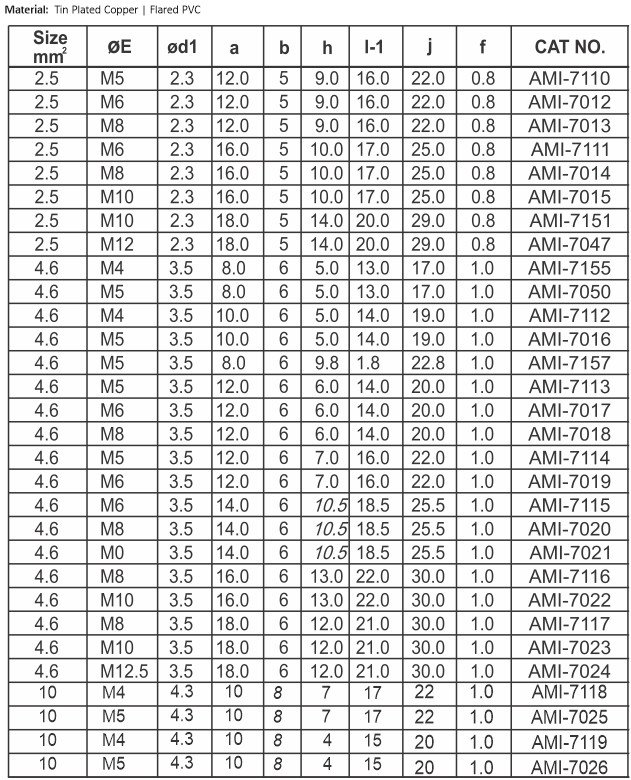

Insulated Copper Ring Tongue Type Lugs:

- Designed for applications where insulation is not a primary concern.

- Ideal for environments where space constraints demand a compact yet robust solution.

- Ensures a secure and stable termination of wires, preventing fraying and enhancing overall connection reliability.

- Well-suited for use in control panels, power distribution systems, and machinery wiring.

Pre-Insulated Copper Ring Tongue Type Lugs

- Combines the benefits of insulation with the convenience of being pre-insulated for efficient installation.

- Saves time and labor costs during the wiring process, contributing to overall project efficiency.

- Provides a comprehensive solution for applications demanding both insulation and ease of installation.

- Ensures a reliable and secure connection while meeting safety standards for a wide range of electrical systems.

Key Features Across Types:

- Crafted from high-quality copper for superior conductivity.

- Versatile applications in power distribution, control panels, and machinery wiring.

- Durable construction capable of withstanding mechanical stress, vibrations, and varying temperatures.

- Options available for different preferences and specific industrial requirements.

- Compliance with industry standards, assuring users of reliability and safety.

- Corrosion-resistant properties, reducing maintenance needs and contributing to longevity.