Insulated Cord End Sleeves

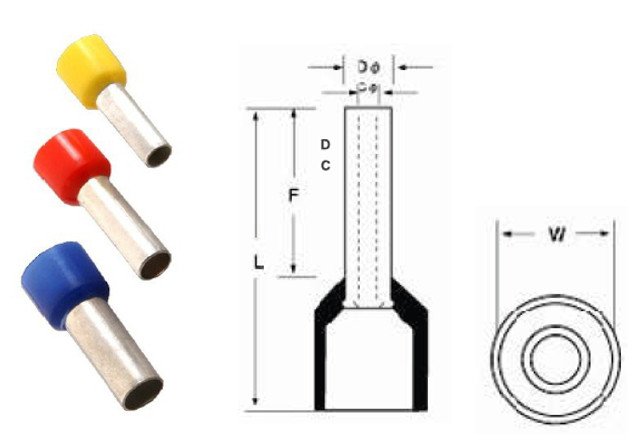

Insulated Cord End Sleeves, often referred to as cord ferrules or wire end sleeves, represent indispensable components in the realm of electrical and industrial engineering. Crafted from insulating materials like plastic or metal, these small cylindrical devices are meticulously engineered to be crimped onto the exposed ends of electrical wires or conductors. Their primary function lies in fortifying and refining electrical connections, ensuring both reliability and safety within diverse applications.

By encapsulating wire ends, these sleeves mitigate the risk of fraying, enhance mechanical stability, and prevent potential short circuits or wire exposure. Their versatility extends to facilitating easy identification and organization through color-coding, adhering to industry standards, and providing resistance to varying environmental conditions.

Versatile Applications in Industry: Unleashing the Power of Insulated Cord End Sleeves

Enhanced Electrical Connections: Insulated Cord End Sleeves improve the reliability of electrical connections by providing a secure termination point for wires. They prevent fraying, ensure a solid connection, and protect against potential short circuits or exposed conductors.

Strain Relief: These sleeves add mechanical stability to the wire termination point, reducing the risk of damage from vibrations, tension, or bending. This is crucial in environments where machinery or equipment undergo frequent movement or stress.

Prevention of Wire Strand Exposure: By encasing the wire ends, these sleeves prevent the individual strands from splaying or being exposed, which could lead to electrical hazards, corrosion, or decreased conductivity.

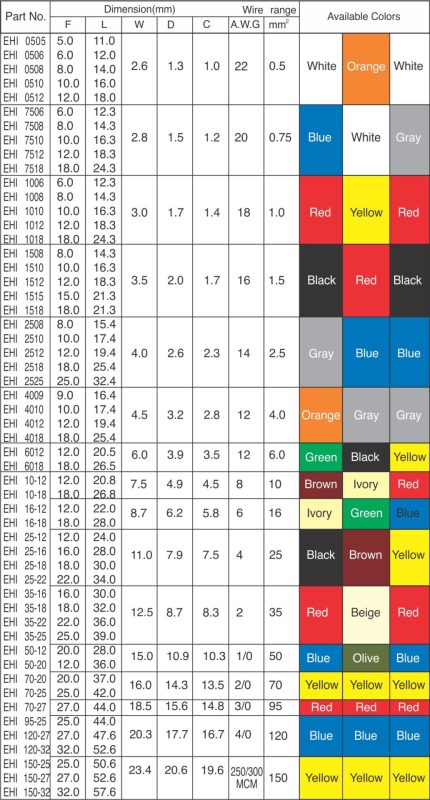

Identification and Organization: Insulated Cord End Sleeves are often color-coded based on wire size, making it easier to identify and organize wiring within complex systems. This aids in maintenance, troubleshooting, and repairs.

Compliance with Standards: In many industries, the use of insulated cord end sleeves is mandated by safety and electrical standards. They contribute to compliance with regulations, ensuring that electrical systems meet required safety and performance criteria.

Easy Installation: The crimping process for attaching insulated cord end sleeves is relatively simple, allowing for quick and efficient installation. This ease of use is essential in industries where time and precision are crucial factors.

Temperature and Chemical Resistance: Depending on the material used, insulated cord end sleeves can provide resistance to temperature variations and exposure to certain chemicals, enhancing the durability and lifespan of electrical connections in challenging environments.

In summary, insulated cord end sleeves play a crucial role in maintaining the integrity and safety of electrical connections in various industrial applications. Their versatility, ease of use, and compliance with standards make them an essential component in wiring systems across different sectors.