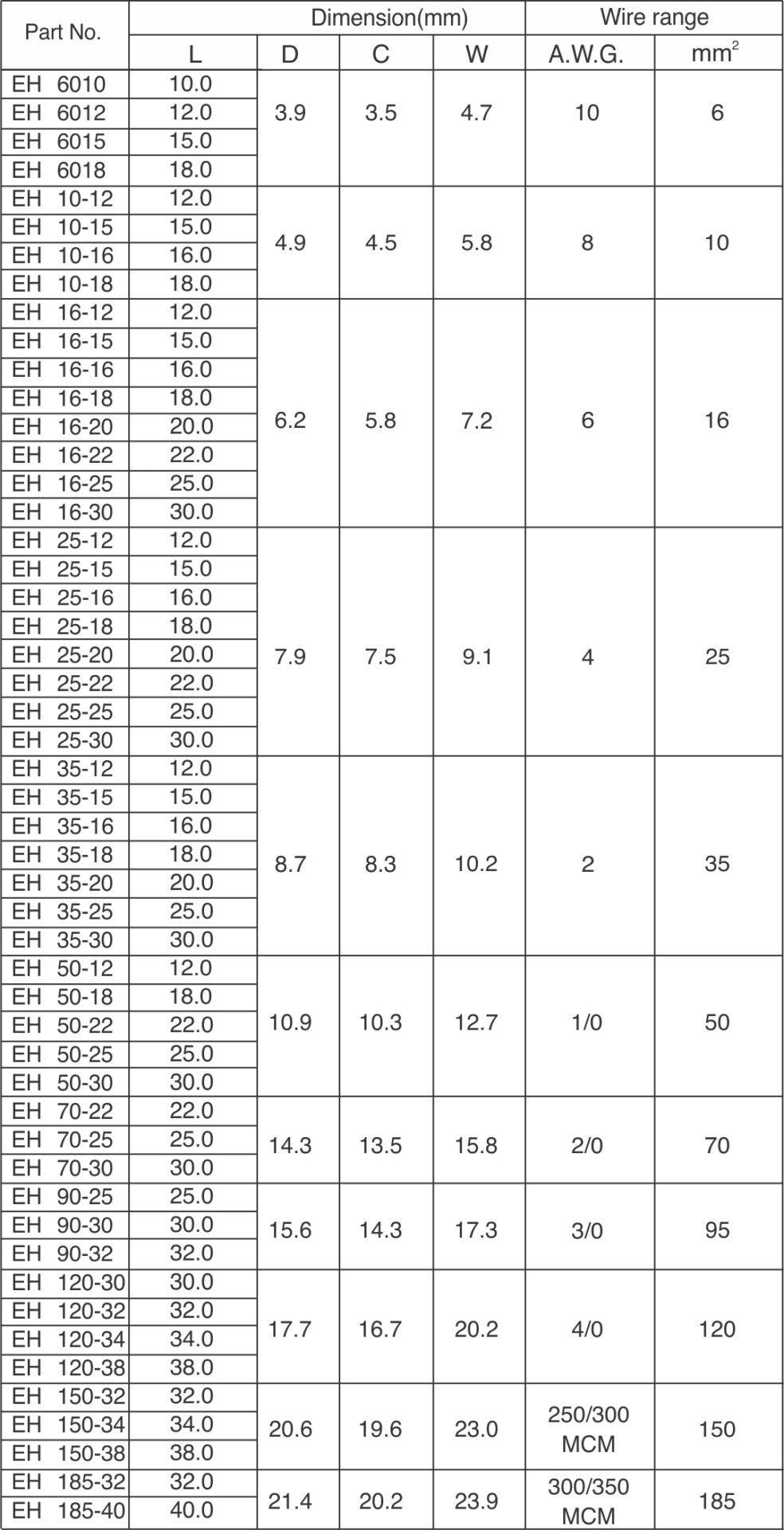

Non Insulated Cord End Sleeves

Non-insulated cord end sleeves, made from tin-plated copper, are small cylindrical ferrules used in electrical applications to terminate stranded wire ends. These sleeves serve a crucial role in ensuring secure and reliable connections within electrical systems. The tin plating enhances conductivity and provides resistance against corrosion, contributing to the longevity and effectiveness of the electrical connections.

Powering Precision: Unleashing the Potential of Non-Insulated Cord End Sleeves in Industry

Enhanced Conductivity: Tin-plated copper ensures optimal electrical conductivity, promoting efficient power transmission in industrial applications.

Corrosion Resistance: The sleeves’ corrosion-resistant properties contribute to the longevity of electrical connections, reducing maintenance requirements.

Space-Efficient Design: Non-insulated cord end sleeves offer a compact solution for industries facing space constraints in wiring setups.

Reliable Terminations: These sleeves secure wire ends, preventing fraying and ensuring a stable electrical connection, enhancing overall system reliability.

Versatility: Suitable for various applications, including control panels, power distribution systems, and machinery wiring, making them a versatile choice in industrial settings.

Durability in Harsh Environments: Built to withstand challenging conditions, these sleeves maintain their effectiveness even in harsh industrial environments.

Cost-Effective Solution: Non-insulated cord end sleeves provide a cost-efficient alternative for industries seeking durable and reliable wire termination solutions.

In conclusion, non-insulated cord end sleeves, crafted from tin-plated copper, stand as a pivotal component in industrial electrical systems. With their enhanced conductivity, corrosion resistance, and space-efficient design, these sleeves offer a reliable and versatile solution for a range of applications. Ensuring durability in harsh environments, they contribute to the longevity and efficiency of electrical connections, making them a cost-effective choice for industries prioritizing precision and reliability in their operations.

In conclusion, non-insulated cord end sleeves, crafted from tin-plated copper, stand as a pivotal component in industrial electrical systems. With their enhanced conductivity, corrosion resistance, and space-efficient design, these sleeves offer a reliable and versatile solution for a range of applications. Ensuring durability in harsh environments, they contribute to the longevity and efficiency of electrical connections, making them a cost-effective choice for industries prioritizing precision and reliability in their operations.